Fluorinated Electroactive Materials

High performance Piezotech® polymers are made from select combinations of vinylidene fluoride (VDF), trifluoroethylene (TrFE), 1,1-chlorofluoroethylene (CFE), and/or chlorotrifluoroethylene (CTFE). Two product families are available with different electroactive properties.

P(VDF-TrFE) Copolymers

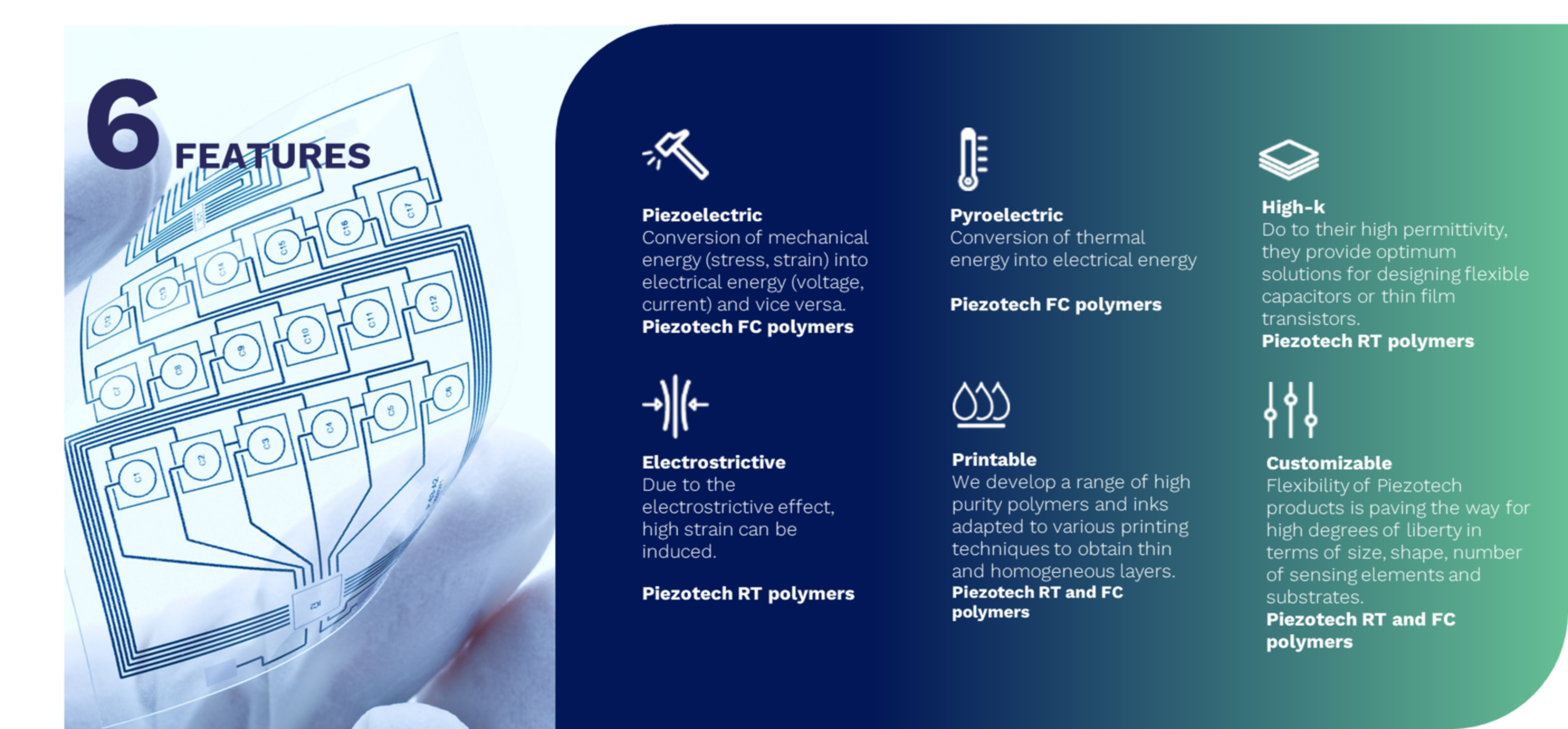

Piezotech® FC is a range of P(VDF-TrFE) fluorinated copolymers. These semi-crystralline polymers are piezoelectric, pyroelectric, and ferroelectric.

Piezotech® FC copolymers are an excellent choice for sensors, energy harvesting, actuators, speakers, ferroelectric memories.

P(VDF-TrFE-CTFE) & P(VDF-TrFE-CFE) Terpolymers

Piezotech® RT is a range of P(VDF-TrFE-CTFE) and P(VDF-TrFE-CFE) terpolymers. These terpolymers exhibit remarkable high-k, electrostrictive, and electrocaloric properties.

Piezotech® RT terpolymers are particularly advantageous for high-k dielectrics in OTFT, actuators, and electrocaloric devices.

Piezotech® Electroactive Materials are available as:

Powders

P(VDF-TrFE) copolymers, and P(VDF-TrFE-CTFE) or P(VDF-TrFE-CFE) terpolymers are produced via a unique process resulting in high purity and low volatile content. Polymers in powder form can be melt processed directly or formulated into inks for the printed electronic market.

Inks

Piezotech® polymers dissolve readily into a wide range of solvents. They can be formulated into inks with various viscosities and dry contents. These inks can be processed via routine printing techniques, including screen-printing, spin coating, solvent casting, slot-die coating, ink-jet printing, and roll-to-roll processes.

Films

Electroactive films of Piezotech® materials can be produced from the melt or by ink casting.

Small film samples (12*12 cm) are available for prototyping and R&D laboratories.

Large film quantities and rolls of films can be produced with a partner by solvent casting on a wide range of substrates.